Mould cleaning:

TECHNICAL ARTICLES, O-RING, GASKET

The most common production process of technical items, o-rings and gasket is to mold by injection of molten rubber into molds. In general, the molds are made of steel, sometimes chromed or with a particular surface treatment.

The maintenance of these molds is a key factor to ensure a high level of quality of the finished product. Especially in recent years, with the adoption of increasingly complex and detailed molds capable of meeting the needs of an increasingly demanding market.

The main challenges to be overcome in the cleaning of molds for the production of technical articles, o-rings and gasket are: the removal of the release agent layer, the removal of the residual fumes generated by the injection and compression operations of the melting rubber and the removal of rubber residues, especially in smaller joints and inlets.

The specific BicarJet process designed for mold cleaning allows to clean complex molds with the utmost accuracy, even with residues of the latest generation compounds: NBR, HNBR, VITON and Fluoroelastomers.

TOTAL CLEANING

Our cleaning system ensures complete removal of residues even in the smallest cavities and in the most complex geometries.

EFFECTIVE ALSO ON UNDERCUT

The effectiveness is also guaranteed in the cleaning of the undercuts.

NOT ABRASIVE

The BicarJet system does not damage the surface of the mold, it preserves the burr-cutters, the chrome plating and the sharp edges.

SAFE FOR THE OPERATOR

The use of low pressures, bicarbonate foodgrade and the total absence of chemical products makes the BicarJet solution the safest for the operator.

EASY TO USE

All our solutions are built in Italy keeping in mind the ease of use for the operator.

DEEPER CLEANING

The special bicarbonate used has a grain size designed to effectively treat even moulds with the smallest cavities.

INTACT MOLDS

The micro bicarbonate particles, fired on the molds, disintegrate in the impact taking away the dirt with them, without scratching the surfaces.

Bicarjet has designed a process that combines the strength of baking soda with a dedicated technology to guarantee maximum efficiency and safety for treated surfaces and for operators.

That's why:

EFFICIENT

- Performance in cleaning

- Reliable over time

- Does not damage the molds

CHEAP

- Low investment

- Low operating costs

- Reduced maintenance

SURE

- Use food-grade baking soda

- Low working pressure

- Without chemicals

FLEXIBLE

- Tailor-made commercial solutions

- Equipment rental service

- Continuous assistance

Mold cleaning for rubber and technical items:

le macchine

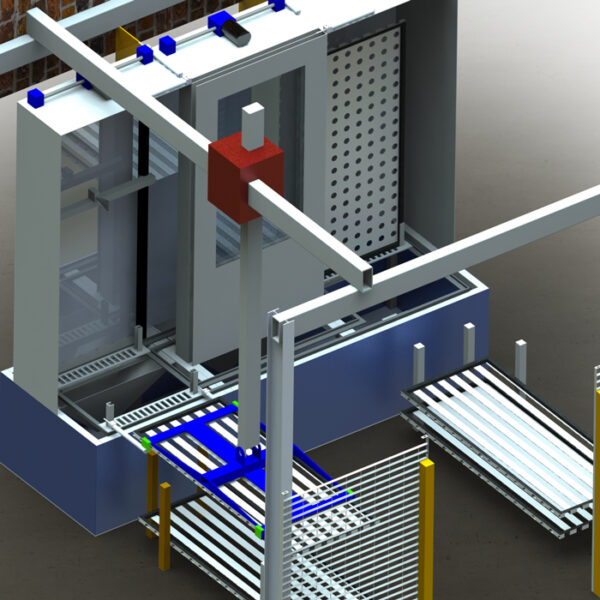

The Automatic AM1600 system, is the solution for surface cleaning of molds for gasket and…

We create customized cleaning and surface treatment solutions. We support the customer in all phases…

We create customized cleaning and surface treatment solutions for molds for technical items, o-ring and…

Ecoloop is BicarJet’s innovative recirculation solution: compared to traditional systems, it uses a supersaturated mixture…

The MJ1000 cabin is the ideal solution for mold cleaning in the production of technical…

The MJ900 cabin is the ideal solution for mold cleaning in the production of technical…

The MK1500 cabin is the ideal solution for mold cleaning in the production of technical…

Contact us!

- Via Nona Strada, 4, 35129 Padova PD

- +39 049 780 8036

- info@bicarjet.com